In February, nearly two-thirds of KFCs across the United Kingdom were closed or offered a limited menu after its new distributor failed to deliver enough chicken on time. With no backup plan for how to get more chicken, customers took to social media to vent their frustrations at the fast-food restaurant chain. While KFC tried to handle the response to the supply chain problem with grace and good humour, customers haven’t been quick to forgive and forget. And, even now, the disruption and limited menus remain an issue.

KFC don’t just have their customers to contend with. The costs of a disruption like this can be seriously damaging. The company made a decision to continue to pay their staff according to their salary rate or their average working hours, depending on contract types. Whilst staff were advised to take annual leave during the most serious period of disruption, they were not forced to.

KFC also have the loss of sales revenue to factor in. Whilst the cost implications of this disruption are yet to be confirmed, it’s suggested the giant could have lost up to £1 million per day.

Considering 80% of KFC restaurants are franchised, they must also ensure these relationships are protected and those franchises are responding positively and consistently to the disruption.

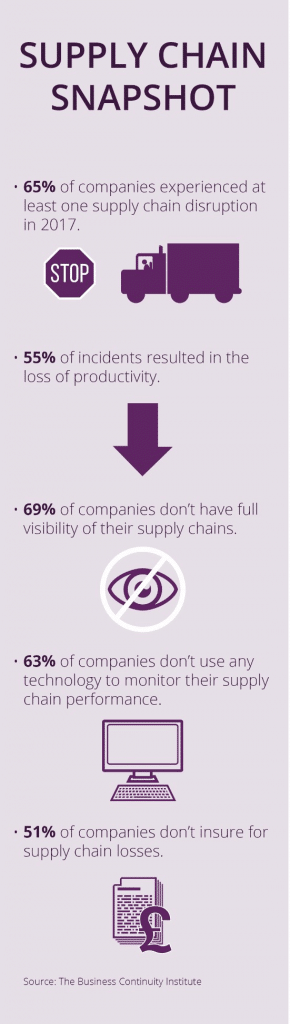

Unfortunately, supply chain disruptions like this are not uncommon. In fact, 65 per cent of UK businesses experienced at least one supply chain disruption last year, according to the Business Continuity Institute. These disruptions can be especially damaging, as 55 per cent of them lead to a loss of productivity.

Some of the potential losses may be mitigated through the appropriate cover, but 51 per cent of businesses don’t insure their supply chains at all.

To reduce your supply chain risks, consider adopting the following:

• Conduct regular audits and inspections of your suppliers to ensure that they are taking the necessary precautions to avoid business interruptions.

• Invest in monitoring technology to receive up-to-date information about the status and health of your supply chains.

• Organise a contingency plan in case there’s an issue with your supplier.

• Contact A-Plan to discuss what appropriate covers can protect your business.